24 Jun Acme Printing Buys New Screen Printing Press

We’ve all received t-shirts with company logos or the names of events printed on them, but do you know how that image is transferred onto the shirt? The process is called screen printing. This process can be a little difficult to master, but it can yield beautiful results. Acme Printing recently purchased a Riley 350 6 Color 6 Station Screen Printing Press, a state-of-the-art manual press, to help us achieve high-quality custom screen printings with a faster turnaround time.

What is Screen Printing?

Screen printing is the process of transferring an image onto fabric using a screen and ink. Silk screens were first used to apply images to fabric in China as early as the 900s. The process has continued to improve over time as innovations in technology have been made. Today, the screens used in screen printing are usually made from synthetic threads, such as polyester, instead of silk. Screen press machines are also now used to increase quality, consistency, and speed of the process.

How Does Screen Printing with a Screen Press Work?

The first step in screen printing is acquiring an image. Almost any digital image file can be printed onto clear film to create an artwork positive. This means the image is printed in black so that light cannot shine through it. Once the image is printed on film, it can then be burned onto the screen in the dark room.

In order to burn an image onto a screen, the screen must first be coated in an emulsion. An emulsion is a liquid that hardens when exposed to UV light. The film with the positive image is placed between the emulsion-covered screen and the light source in the exposure unit. When the emulsion is exposed to the light in the exposure unit, it hardens and becomes impermeable to ink. Because the positive image blocks light from reaching the emulsion, the emulsion behind the image does not harden and remains a liquid. The screen is then rinsed with water to remove the liquid emulsion, leaving the image burned onto the screen. Once the screen dries, it can then be used on the screen press.

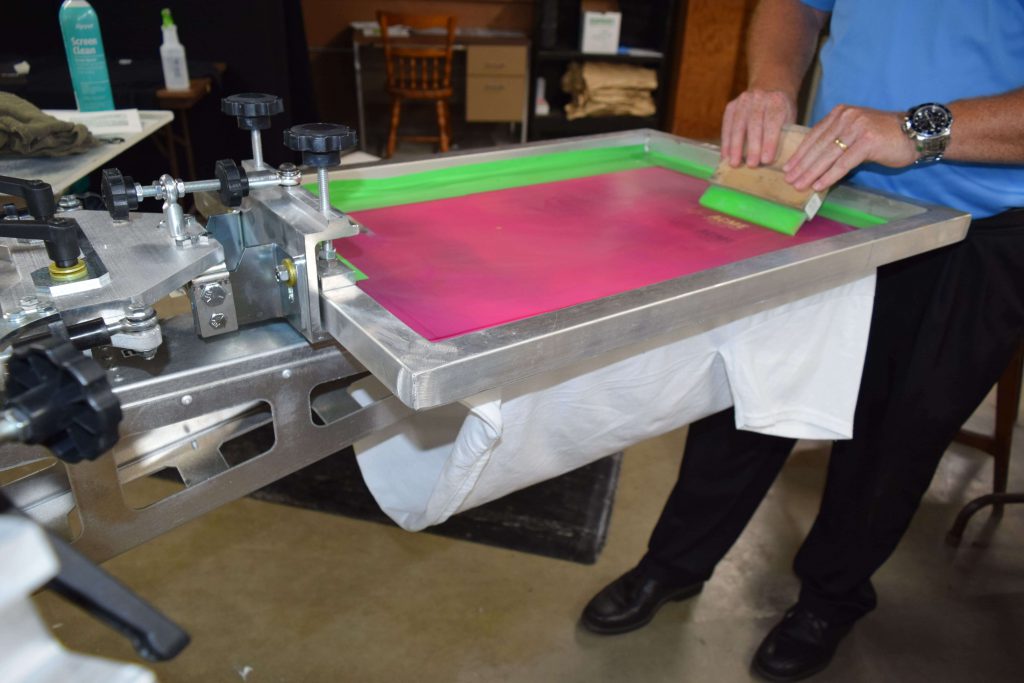

The screen press is where the real magic happens. The screen is locked into place on an arm of the machine and maneuvered into position, and a shirt is placed over a palette. The desired colored ink is added to the screen, which is then lowered onto the shirt. The machine operator glides a squeegee across the screen to push the ink through the screen onto the shirt. The ink will only pass through the screen in the open stencil area where there is no emulsion. This means the ink will be transferred onto the shirt only in the desired design. If the design requires more than one color, then the shirt will need to be flash dried after each color. The flash dryer sets the ink to a gel-like consistency so that the next color will stick on top of the previous color without running together.

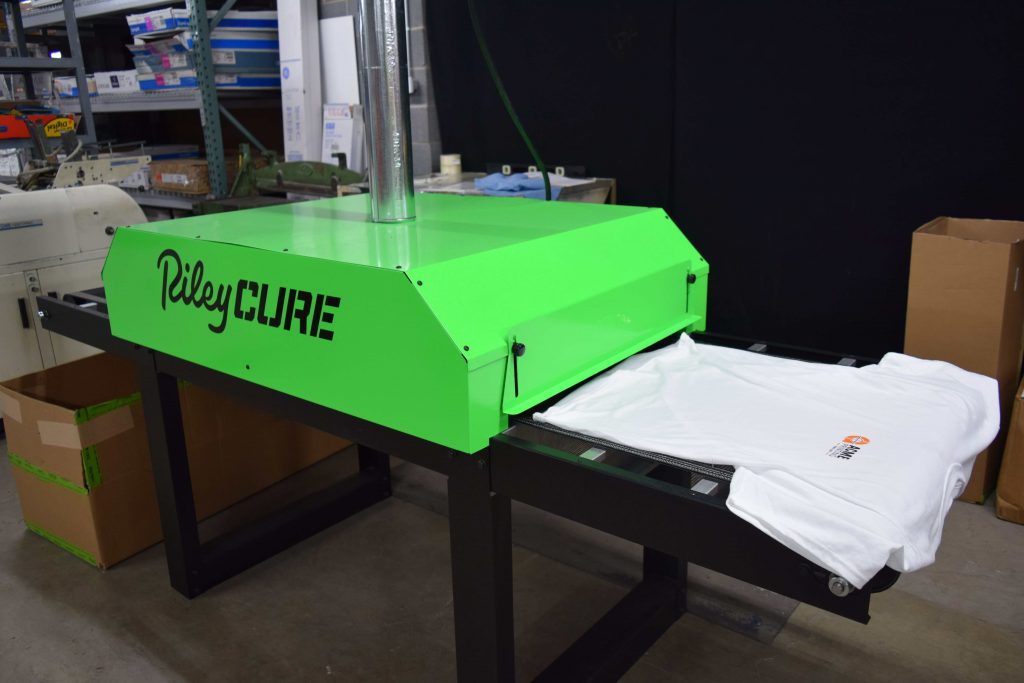

Once every color of the design is pressed into the shirt, the ink must be cured. The ink needs to be heated at a certain temperature for a certain amount of time to cure so that the design sets into the shirt and will last for a long time. To cure the ink, the shirt is placed on a conveyor belt that passes through a heater set to the correct temperature and speed. Upon exiting the heater, the shirt is ready for delivery.

Why the Riley 350 Screen Press?

Acme Printing chose to purchase the Riley 350 Screen Printing Press for many reasons. The screen press has six arms for six different colors to be used at once, and it has six palettes so that six shirts can be screen printed at a time. Both the arms and palettes spin so that the colors and shirts can be rotated around to different stations. This increases the speed at which we can print on shirts, allowing for shorter turnaround times. The machine also allows us to have more control over the quality of the shirts. We can adjust the position of the screen over each shirt down to very specific angles, which means we can be sure that each design will be printed in the correct spot and in the same exact location on each shirt in the order. Because the Riley 350 is a manual press, our machine operator physically handles and inspects each shirt to ensure the customer only receives the highest quality prints. If for some reason any mistake is made, it is caught well before the shirt makes it to the customer.

Custom Screen Printing in Morristown, TN

Do you need custom printed shirts for an upcoming event? With our new screen printing press, Acme Printing can provide you with high-quality prints, and since we are printing at our local workshop, you will experience a quick turnaround time. We’d love to help you get started on your next screen printing project. Give us a call at 855-581-8528 or visit our website.

Sorry, the comment form is closed at this time.